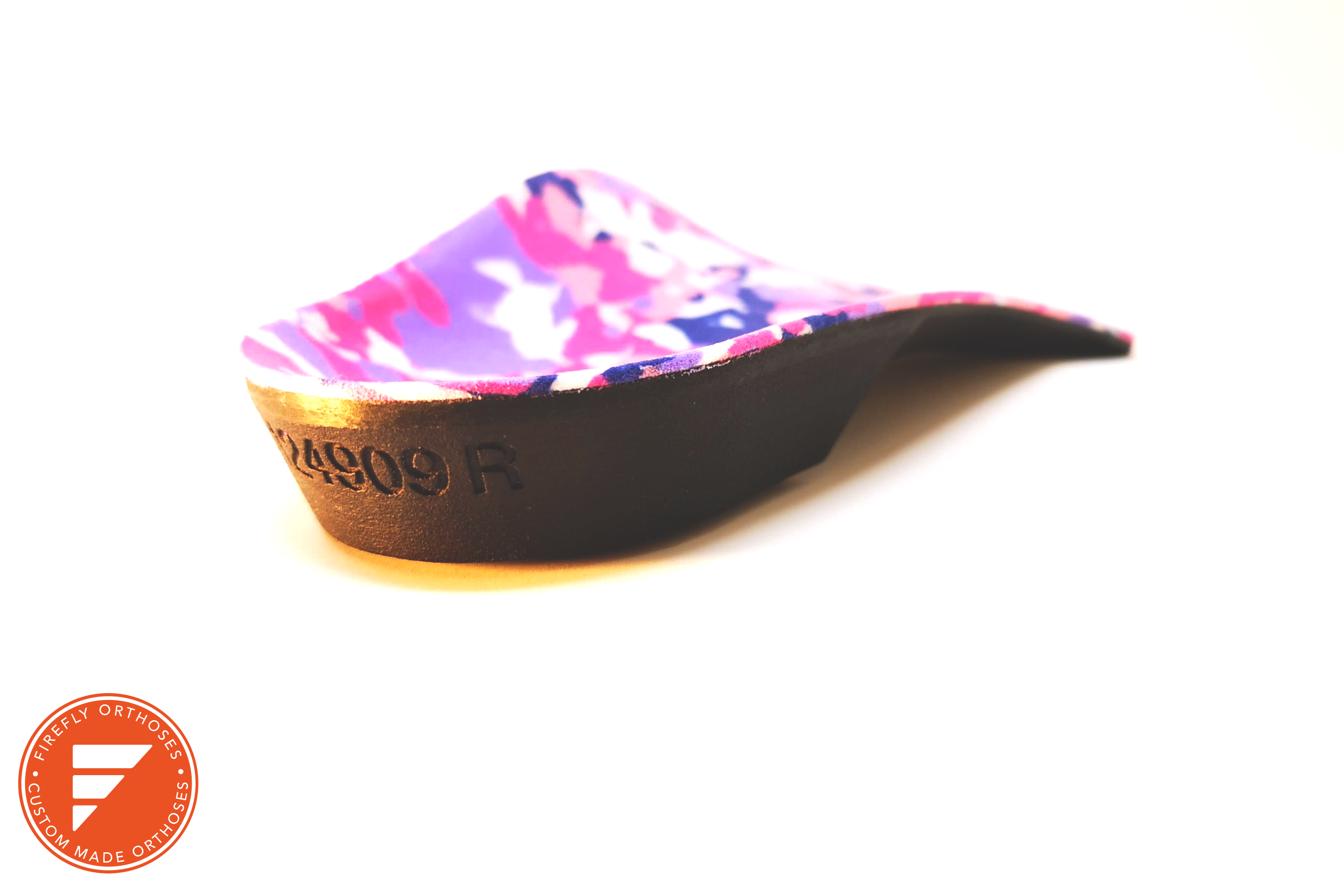

Firefly reveal first 3D printed foot orthotics

We are excited to announce the production and distribution of our first batch of 3D printed foot orthotics. The move to produce 3D printed orthotics is part of a company-wide policy of adopting more processes and procedures that align with current and future technologies, both in the manufacture of orthoses and in how podiatrists interact with their patients during the prescription processes.

Initial sets of 3D printed orthotics have been produced and shipped to select Firefly associate podiatrists.

Developments in technology have allowed for new manufacturing methods to produce products that offer more benefits for both the podiatrist and patient.

Our state of the art devices are constructed by a multi-jet fusion process which provides unprecedented design freedom for Firefly to create innovative designs to help the podiatrist achieve better patient outcomes.

Our 3D printed range will allow for quicker turn around times which means the podiatrist can have prescription orthoses back with the patient for fitting quicker.

For the patient, the manufacturing technique changes the boundaries of what is achievable. Firefly is working on innovative designs that will allow the podiatrist treat complex foot and ankle pathologies by selecting from a suite of 3D printed device types with novel design features. Lower-level patient benefits include personalisation of devices by potentially incorporating the patients name in the product design.

Greater numbers of Firefly associate podiatrists are using the iOS/Structure Sensor scanning combination to capture patient foot data. This has lead to Firefly producing our own iPad scanning application that is due for release in the coming months.